Our extensive hands-on expertise is backed by ten state-of-the-art facilities across the U.S. and the U.K., providing preclinical through commercial scalability and impressive scope, with a total cGMP footprint of approximately a million square feet. From increased sterile fill-finish capabilities to dry powder development, your product benefits from our combination of cutting-edge technology and high capacity.

Our global facility footprint

Select each location for a deep dive into what our facilities can offer you.

Union City

Union City is a 10,500 sq. ft. (~975 m2) research and formulation facility. We provide services in the early stages of device selection, formulation design, analytical testing, cGMP release testing, and product and process development and scale-up.

Union City at a glance:

- Expertise in all stages of product development and cutting-edge technologies

- Inhalation drug delivery (IDD) development

- Particle engineering

- Dry powder formulations

- Liquid formulations (nebulizers)

- Offers fast track to first clinic

Northridge

Northridge is a 286,000 sq. ft. (~26,570 m2) scale-up and commercial manufacturing facility. We manufacture inhalation drug delivery and transdermal drug delivery products at this location.

Northridge at a glance:

- On-site cGMP Quality Control laboratory ensures we meet client expectations while being in full regulatory compliance

- pMDI pressure and cold filling

- pMDI packaging

- Transdermal coating

- Transdermal converting

- Transdermal packaging

Bridgeton

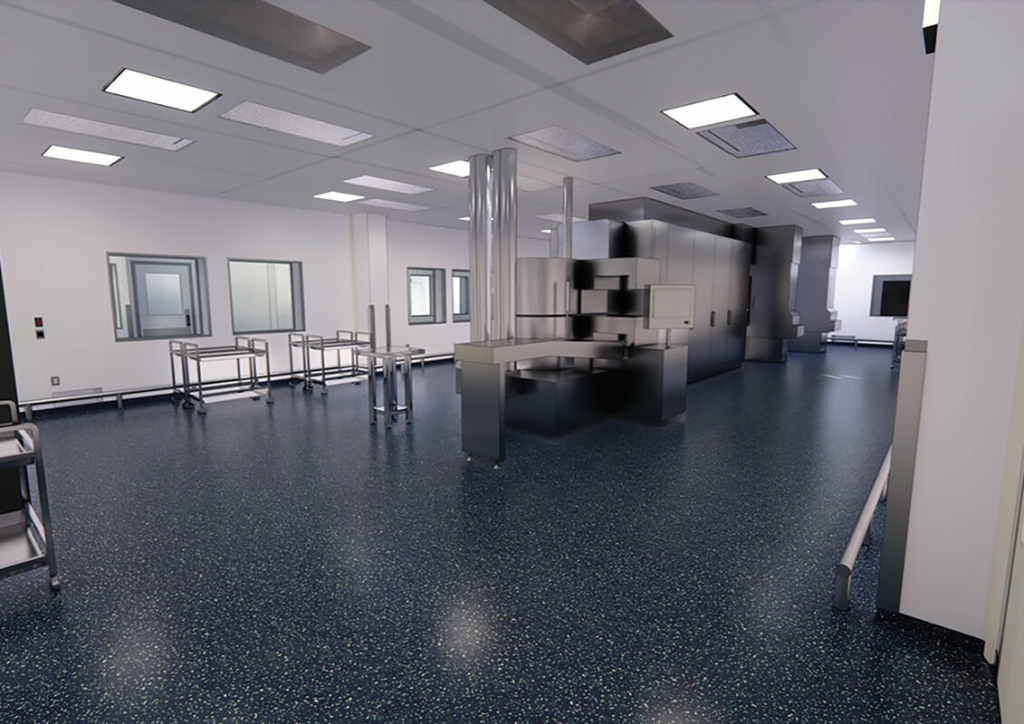

Opening in 2024, our new, world-class facility in Bridgeton, Missouri, offers 155,000 sq. ft. (~14,400 m2) devoted to aseptic operations, including two labs, two formulation suites, and almost 11,000 sq. ft. (~1,022 m2) of fill suites. It also houses best-in-class sterility assurance isolator and automation technology.

Bridgeton at a glance:

- Designed for max efficiency, compliance, and patient safety

- Annex 1 compliance with every line

- Isolator sterility assurance technology standard

- 3 isolator high-speed filling lines

- Utilities sized to support up to 7 lines

- Rapid line changeover

- Independent filling suites

- Syringe, cartridge, and vial filling

- Formulation

- Automated PUPSIT testing

Woodbury

Woodbury is a 140,000 sq. ft. (13,006 m2) research, formulation, and development facility. Kindeva also provides regulatory consultation and warehousing with room for expansion at this location.

Woodbury at a glance:

- Offers high efficiency heating and air handling, LED lighting, networked connections

- cGMP clinical manufacturing space — clean room facilities with 7 process rooms

- Development laboratory with full range of capabilities including plume geometry, spray pattern analysis, extractables, and leachables

- Lab scale filling with any propellant (134a, 227ea, 152a, and 1234ze)

- Stability chambers with 24/7 monitoring (across full range of ICH stability conditions)

- Phase I intradermal manufacturing

Brentwood

Brentwood is a 91,760 sq. ft. (8,525 m2) aseptic operating and support manufacturing facility. It also includes warehousing and administrative offices on-site.

Brentwood at a glance:

- Fully licensed and integrated single- and dual-chamber autoinjector capability

- Formulation

- Sterile filtration

- Aseptic processing of autoinjector drug cartridges

- Engineering

- Quality control labs

Maryland Heights

Maryland Heights is a 174,850 sq. ft. (16,244 m2) inspection, device assembly, and packaging facility that manufactures finished autoinjector units. It also houses administrative offices.

Maryland Heights at a glance:

- Offers regulatory, finance, environmental health and safety, and global trade support

- Engineering and product development

- Inspection

- Labeling

- Packaging

- Warehousing

- Distribution

Lexington

Our 55,000 sq. ft. (5,109 m2) facility in Lexington, KY, houses our nasal spray operations, including development, manufacturing, and analytical support capabilities.

Lexington at a glance:

- cGMP nasal spray manufacturing

- Formulation

- Filling

- Assembly

- Labeling & packaging

- Clinical & commercial production

Germantown

The Germantown, Maryland, facility (a short drive from Washington, D.C.) houses Kindeva’s Combination Product Development Center of Excellence. The site includes laboratory, office, and conference room space.

Germantown at a glance:

- Drug delivery device strategy, landscaping, and selection

- Industrial design and human factors engineering

- Solid modeling, simulation, and computational analysis

- Prototype fabrication and testing

- Test method development and qualification

- Functional investigation

- Environmental stress testing, ship testing, aging

- Device process development and tech transfer

- Combination product regulatory strategy

- Combination product quality management system (QMS) and design history file (DHF)

Clitheroe

Clitheroe is a 51,500 sq. ft. (4,785 m2) scale-up and commercial manufacturing facility. It is one of two Kindeva facilities located in the United Kingdom.

Clitheroe at a glance:

- Specializing in small and large drug-delivery device solutions and innovations

- pMDI valve, can, and sleeved can manufacture

- Supply of coated cans and componentry

- Low-GWP propellant friendly component development

Loughborough

Loughborough is a 150,000 sq. ft. (13,935 m2) research, formulation, development, scale-up manufacturing, and commercial manufacturing facility. It is one of two Kindeva locations in the United Kingdom, and it includes an extensive cleanroom facility.

Loughborough at a glance:

- Offers on-site CMC strategy and regulatory department with global product registration experience

- Independent quality organization

- MPS knowledge and capabilities

- Microbiology laboratories

- Analytical method development and validation

- pMDI pressure and cold filling

- Packaging and one-site QC laboratory

- Clinical supply

- Nasal

- Pilot-scale filling with any propellant (134a, 227ea, 152a, & 1234ze)

- BAI packaging

- Development laboratory with full range of capabilities from feasibility to commercial scale

- Stability chambers with 24/7 monitoring (across full range of ICH stability conditions)

- Transdermal drug-in adhesive systems, integrated patch overlay systems, and gel patches

- Intradermal solid and liquid formulations delivered

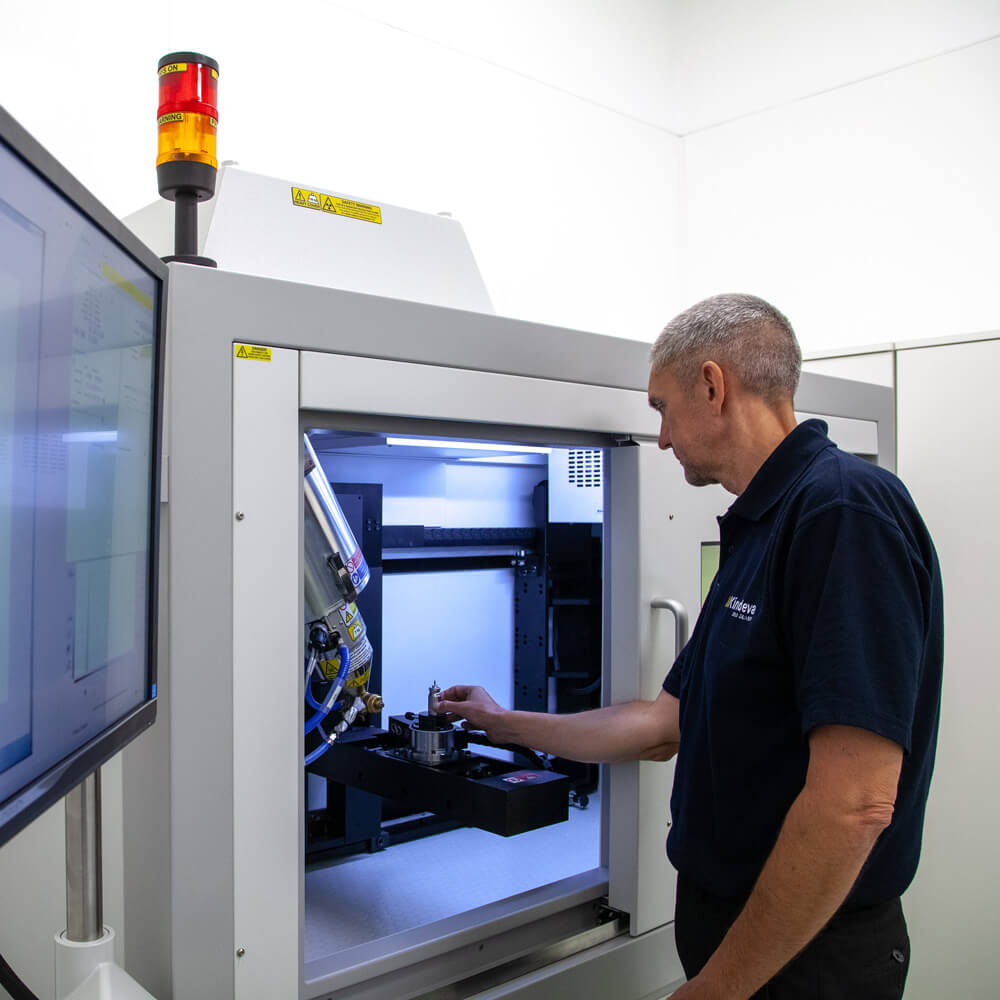

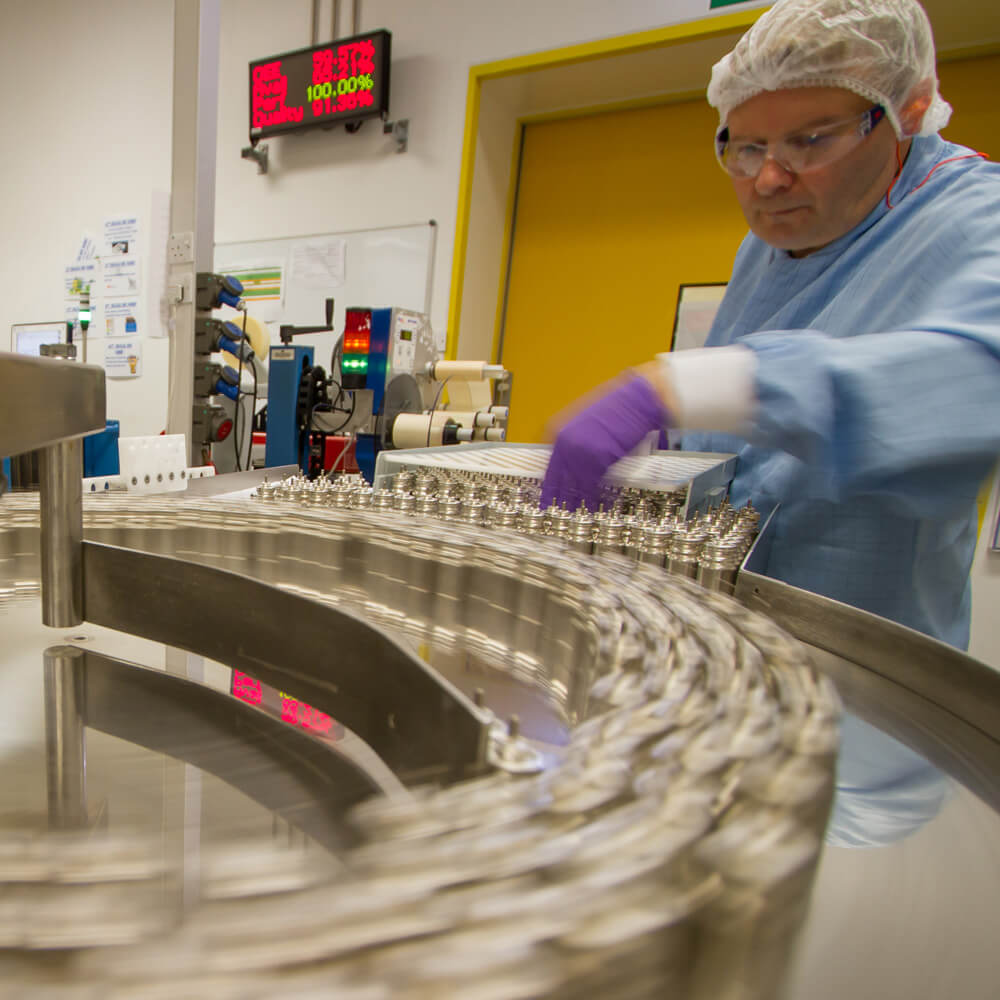

The power behind your product

Your product is expertly developed using only the most cutting-edge technology available.

Bringing best in class sterile fill-finish to Bridgeton

Introducing our new, world-class facility in Bridgeton, Missouri!

Opening in 2024, it includes more than 155,000 sq. ft. of dedicated aseptic operations space: two labs, two formulation suites, and approximately 11,000 sq. ft. of fill suites.

And with our world-class sterility assurance isolator and automation technology, Kindeva ensures patient safety is always a priority in the products we produce. This investment in innovation greatly expands our fill-finish capabilities while providing additional space for future expansion.

Click on the Bridgeton location on the map above for even more details!