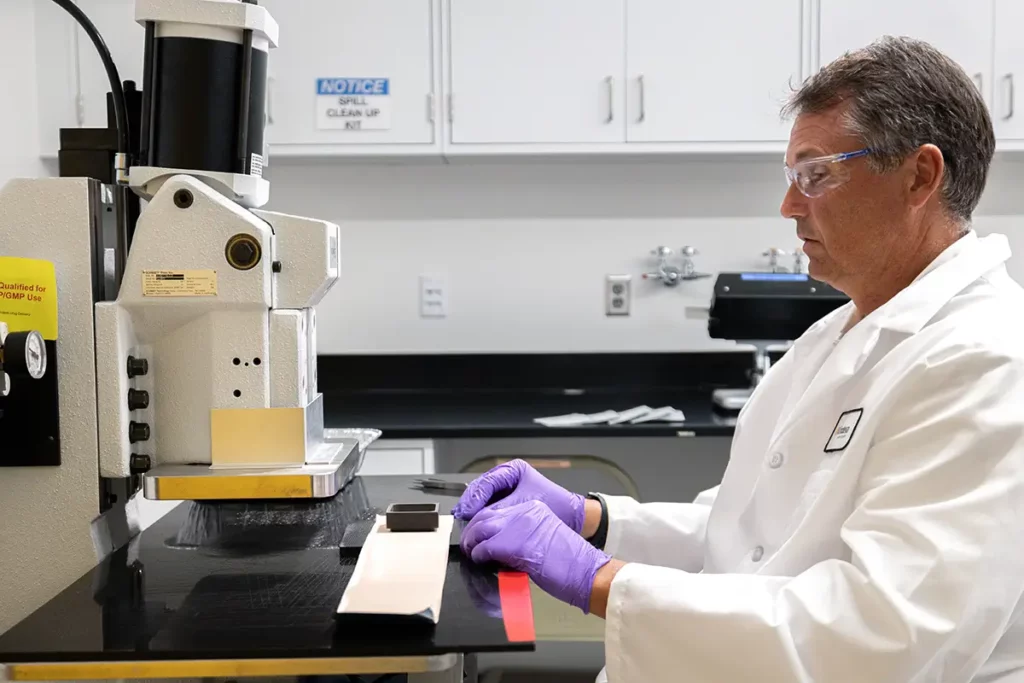

Your therapy is a force for good, and an experienced analytical services partner can help you ensure it meets regulatory standards and delivers the reliability that patients expect and require. With over a century of experience, Kindeva Drug Delivery has the expertise necessary to ensure compliance and quality of your drug, containment system, delivery system, device, or combination product. We perform our analytical and testing services in our Woodbury, MN, laboratory, in accordance with cGMP standards.

Analytical method development & validation

Our analytical services support your product through clinical stage development with rapid response time and expert guidance. We ensure compliance with the most up-to-date USP guidance as well as the rigor of revised regulatory guidance such as ICH and ASTM. Utilizing scientifically justified decisions, methods are developed following a risk-based approach encompassing the life cycle of your product and intended use.

With long-term support, alongside verification and transfer options, Kindeva is here to establish methods which are sustainable from batch release throughout your stability programs.

Raw material testing

Our raw material testing services are adapted to your needs, helping you verify the safety and quality of your product. We execute most USP compendial testing and use a variety of analytical methods and tests, tailored to your unique concerns and considerations specific to your product.

Stability testing & storage

To ensure safety and meet regulatory requirements, you need to understand how your product can change, based on the environment in which it may be stored or transported. Our stability testing services characterize your product’s shelf life under diverse conditions. We have the following ICH storage conditions available: -20°C, 5°C, 25°C/60% RH, 25°C/75%RH, 30°C/65%RH, 30°C/75%RH, and 40°C/75%RH as well as temperature cycling. Other conditions are available upon request to meet the unique needs of your product.

At Kindeva, we specialize in providing comprehensive stability testing services, designed to ensure the efficacy, safety, and quality of your pharmaceutical and biotechnological products throughout their shelf life. Our state-of-the-art laboratories and experienced scientists are equipped to handle all aspects of stability studies:

- Real-time, accelerated, and intermediate stability studies following regulatory, ICH guidelines, and custom protocols that fit your unique product requirements

- Advanced environmental chambers: Our facility boasts a range of environmental chambers, calibrated for various temperature and humidity conditions, ensuring precise and reliable testing environments

- Continuous monitoring: Utilizing the latest technology, we provide continuous monitoring of your products, offering real-time data

- Robust analytical testing: Our laboratory employs validated analytical methods to accurately assess the stability characteristics of your products

Extractables & leachables testing

Compounds from your combination product’s container closure system, delivery system, containment system, and packaging that leach into your drug product can be a safety risk. Identifying and quantifying compounds that can be extracted from the drug product contact materials through aggressive means can inform the design of a leachables study. Leachables testing quantifies leachables that may be present in your drug product, migrating into the product over time under normal use and storage conditions. Kindeva uses a wide range of analytical equipment, including GC, GC/MS, headspace GC/MS, UPLC, and high-resolution accurate mass (HRAM) LC/MS/MS, to identify and quantify extractable and leachable compounds.

Container closure integrity testing

- Expertise and multiple techniques as outlined in USP <1207> deterministic testing

- Container Closure Integrity Testing (CCIT) is essential in the pharmaceutical industry for ensuring the sterility and integrity of pharmaceutical containers, which is crucial for maintaining the safety and efficacy of the products, especially those that are sterile or sensitive to external contamination

Elemental impurity testing

- ICH Q3D Elemental Impurities – Scientific Guideline, USP <232>

- Testing of elemental impurities ensures that your product complies with the ICH Q3D Guideline for Elemental Impurities, demonstrating control of elemental impurities that are either intentionally or unintentionally present due to your product’s raw materials and manufacturing processes

Analytical expertise across delivery formats

Kindeva Drug Delivery’s 100+ years of experience span a wide range of platforms for pulmonary & nasal, injectable, and transdermal drug-delivery formats. Our analytical chemistry and testing services, alongside our expertise across all stages of combination product development and manufacturing, provide unmatched support for your therapy.

Pulmonary & nasal

With a deep understanding of and background in pulmonary & nasal drug delivery, we offer a comprehensive range of inhalation analytical services. From stability testing to simulated patient use studies, Kindeva Drug Delivery supports your product’s development from pre-formulation to commercialization, ensuring your product is safe, effective, and compliant.

Our pulmonary and nasal analytical testing services include:

Injectables

We deliver unrivaled know-how in the injectable delivery space, and our injectables testing and analytical services provide insight into your product’s performance and quality.

Our injectable analytical testing services include:

- Drug content assay

- Drug content uniformity

- Impurities and degradation products

- Extractables and leachables

- Moisture content

- Aggregation – Size exclusion

- Container Closure Integrity testing

- Elemental impurities testing

Transdermal

Kindeva Drug Delivery has more than half a century of experience integrating adhesive, drug, and delivery components. Paired with our analytical expertise, we have the capabilities necessary to provide analytical support for your transdermal product, through every stage of development.

Our transdermal analytical testing services include:

Looking for something else?

Contact our analytical testing experts to find out more about how Kindeva can serve you.

Our commitment to quality

Our team has a demonstrated track record of compliance with regulatory bodies worldwide and Quality by Design (QbD) principles are central to our processes. In line with Kindeva’s commitment to quality, our analytical services are performed in a cGMP laboratory from an FDA-registered facility.

Support your combination product’s path to market

Leverage our industry-leading capabilities, century of analytical experience, and wide range of services to ensure your product meets regulatory requirements throughout its entire life cycle.